Spartronics® Continues Technology Investments with New Generation Flying Probe Test System

Addition of Technology: New Generation Flying Probe Test System

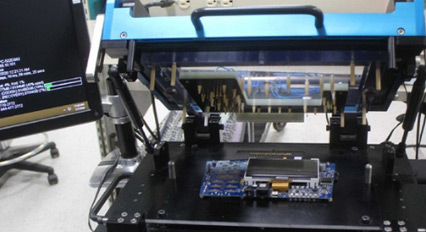

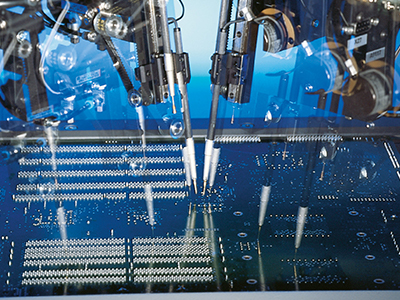

WILLIAMPORT, P.A. August12, 2021 – Spartronics, a leading provider of value-added engineering and electronics manufacturing services for the commercial aerospace, defense, instrumentation and controls, life sciences, medical device, and space markets, is proud to announce that they have acquired to their site the Condor MTS 505 5th Generation Flying Probe Test System offered by digitaltest. The newest investment will be in the Spartronics Williamsport manufacturing facility and continue to support reliable testing methods for customers.

The Flying Probe Tester Condor MTS 505 5th Generation can combine different test methods and can be used universally for all test strategies. Due to the four movable test heads, it offers a high adaptation depth and test coverage. The optional use of fix test pins at the bottom of the DUT additionally reduces the test time and increases the test coverage, overall saving time and money for the customer. The test electronics will be used for performing analog in-circuit tests, functional test, boundary scans and flash on-board programming.

This recent upgrade is part of a series of equipment investments in Williamsport over the last year supporting organizational growth, expanding technology offerings and strengthening our manufacturing capabilities. Additional investments include:

- Increased SMT capacity with the SIPLACE SX placement solution

- Enhancement of the Bowman Series XRF for incoming inspection of leaded products

- Upgrading our contamination test system, lonograph® to the latest model of the SCS lonograph® SMD V

- Upgrading to the next generation of the Cencorp 1300 SR Off-line Router to support lead-free usage and increasing capacity for our Aerospace and Medical markets

- Addition of Nordson Assure™ X-ray Component Counter

ABOUT SPARTRONICS

Spartronics is a leading player in comprehensive, highly complex electronics manufacturing services, ranging from printed circuit board assembly (PCBA) and subsystem integration to high-level product assembly. Our other services include value-added engineering services, manufacturing testing, supply chain management, sustaining engineering, and a suite of aftermarket services to support the full product lifecycle.

With over $400 million in sales, our network of production facilities includes locations across the United States and in Vietnam. Our engineering support is available for end-to-end product development, manufacturing readiness and ramp to production.