Manufacturing Readiness

Speed to Market for your Quality Products

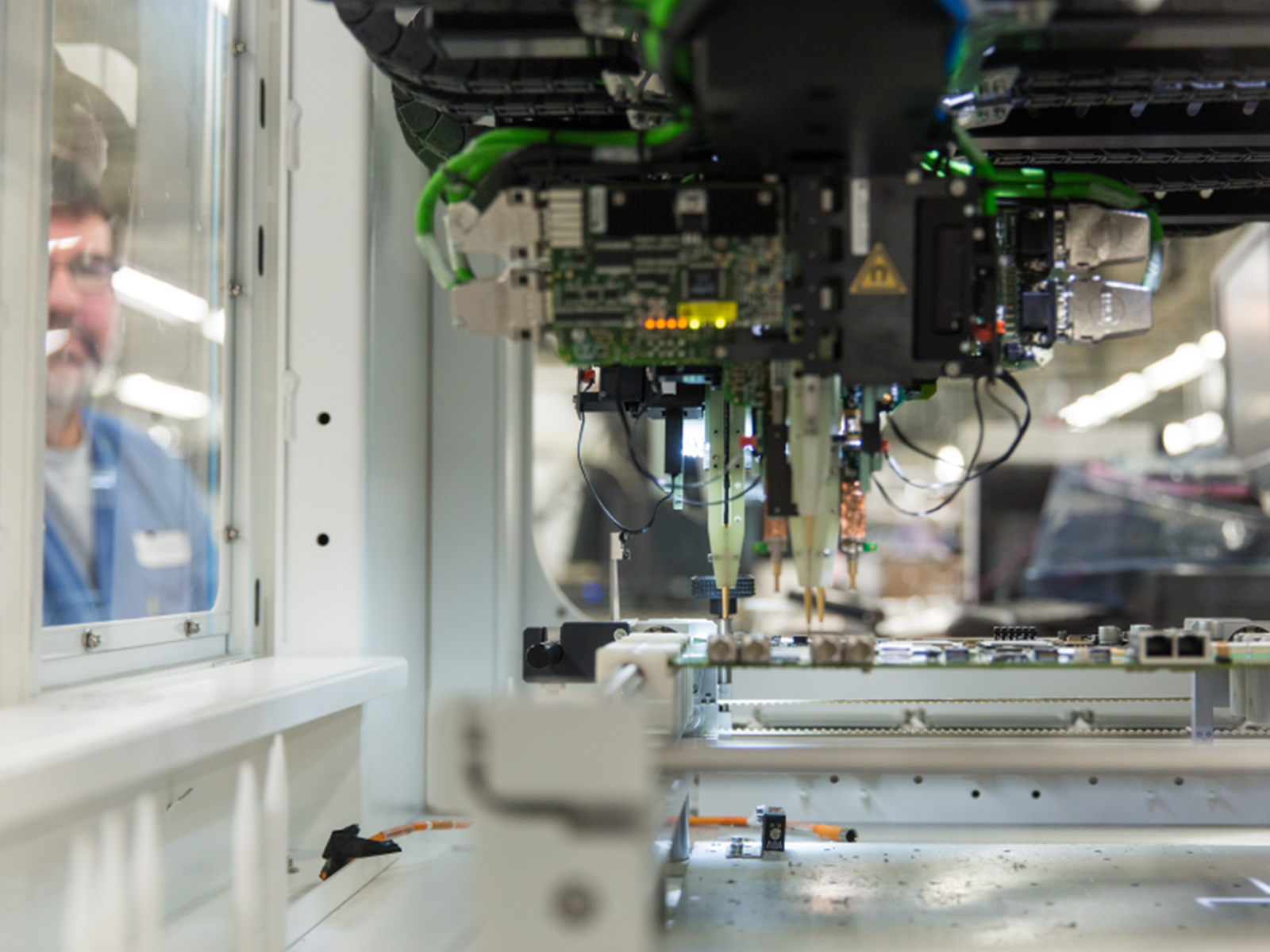

Spartronics provides comprehensive upfront analysis to help OEMs improve product quality, minimize supply chain risks, and accelerate time to market with confidence.

Nimble, Holistic Understanding of Your Manufacturing Needs

Our readiness procedures, process controls and test strategies are consistently applied and documented to ensure products are built to customer specifications.

Spartronics conducts upfront evaluations of all components, designs and fabrication processes to optimize suppliers and technologies. We recommend appropriate alternatives to minimize risks, reduce costs, and help customers to launch and scale their products.

Your Ideal Partner for Contract Manufacturing

Spartronics helps OEMs to ensure their products are:

- In compliance with quality standards and regulatory requirements

- Fully traceable throughout the supply chain

- Sourced through qualified supply chain partners

- Built with fixturing and tooling that enhance efficiency and consistency

- Tested to ensure compliance with requirements and safety

- Refurbished as to extend product lifecycles

- Properly meeting all cleanliness and decontamination requirements

Your Products. On Time. Optimized. Verified.

Count on Spartronics to help you thoroughly analyze your design, materials, supply chain and processes to manufacture complex products on time and within budget. Our manufacturing readiness specialists can help you optimize bills of materials (BOMs), reduce transfer and production costs, and utilize advanced testing to verify that your products are built to strict OEM and regulatory requirements.